The Benefits of Multiphysics Simulation

By the end of this decade, the global electric-vehicle fleet is projected to reach around 250 million, global healthcare systems will be caring for more than 1.4 billion older adults, and the skies above us will hold far more debris than active satellites. Addressing these challenges will call for new technologies and far-reaching designs, developed rapidly, effectively and responsibly. Computer-based simulation is central to this progress, evolving alongside advances in AI, quantum computing, IoT, biotech synthesis and additive manufacture.

In this article, we draw on three decades of simulation at PDD to explore how digital tools now expand the boundaries of design, exploring solutions, accelerating virtual prototype optimisation and verifying design at theoretical limits.

From Early CAD to Multiphysics Simulation

Our first networked 3D CAD (Computer-Aided Design) system, introduced over 30 years ago, was I-deas Master Series, developed by SDRC (Structural Dynamics Research Corporation). We later adopted its Mechanical FEA (Finite Element Analysis) package– fitting, given that FEA had been the foundation of its CAD. FEM (Finite Element Modelling) provided the geometric basis for FEA springboarding SDRC into 3D CAD and CAM (Computer Aided Manufacture) as digital manufacture expanded. SDRC was eventually absorbed into Unigraphics and later Siemens.

Since the 90s, computing power has advanced at a staggering pace, even exceeding Moore’s Law, with its estimate of a 30,000-fold increase. This leap has unquestionably transformed the capability and the practicality of platforms that integrate different forms of physical analysis, such as mechanical, thermal and fluidic, giving rise to the term Multiphysics Simulation. Perhaps more significantly, this vastly increased computing power is user friendly and widely accessible at a reasonable cost.

Only a decade before PDD’s adoption, FEA could still require punched cards, a trip to a corporate or university mainframe computer, and a wait of several days for results. Today, sophisticated analyses can be run, and even animate the results, on a powerful laptop at home.

Expanding Capabilities and Applications

The scope of PDD analysis and simulation has evolved and broadened substantially. Our first PDD analyses were simple, linear stress-strain models using implicit solvers, soon supplemented with non-linear analysis for hyper-elastic materials and high deformations, enabling the development of new seal forms. We progressed to explicit solvers for transient impact analysis, helping us to engineer 6-metre drop tests for industrial instruments, body-worn voice communication to military standards and low-cost, thin-walled medical devices. As our work expanded beyond solid mechanics into thermofluidic analysis, simulation suites offered two distinct advantages:

On the fluidic side, design is often characterised by relatively simple formulae, but applied to complex geometry, with compressible gases and mixed properties rendering classical calculation impractical. Computational Fluid Dynamics (CFD) technology, combined with CAD, manages to number crunch this complexity, helping us to:

- Design medical valves that operate at up to 20Hz

- Blend fluids of different pressures and temperatures in digital showers

- Mix drugs of different viscosities inline at the point of use

- Miniaturise flow management to make medical equipment portable

On the thermal side, simulation has helped us to focus heat sources to achieve maximum temperatures targets and conversely, to dissipate heat silently from sealed, ever more energy-dense mobile devices without leading to excessive surface temperatures.

Ambitious projects increasingly set targets that require multiple forms of simulation to address the challenges of step-change specifications or performance improvements. At PDD, we often find our teams working on these far-reaching programmes that need the full armoury of simulation tools- rigid and elastic mechanical, impact, fluids and thermal- to deliver on the concept vision.

Recent examples of such projects include the development of wearable and ambulatory dialysis solutions and the design of sub-pavement Electric Vehicle (EV) charging systems for urban streets.

Applying Multiphysics in Practice

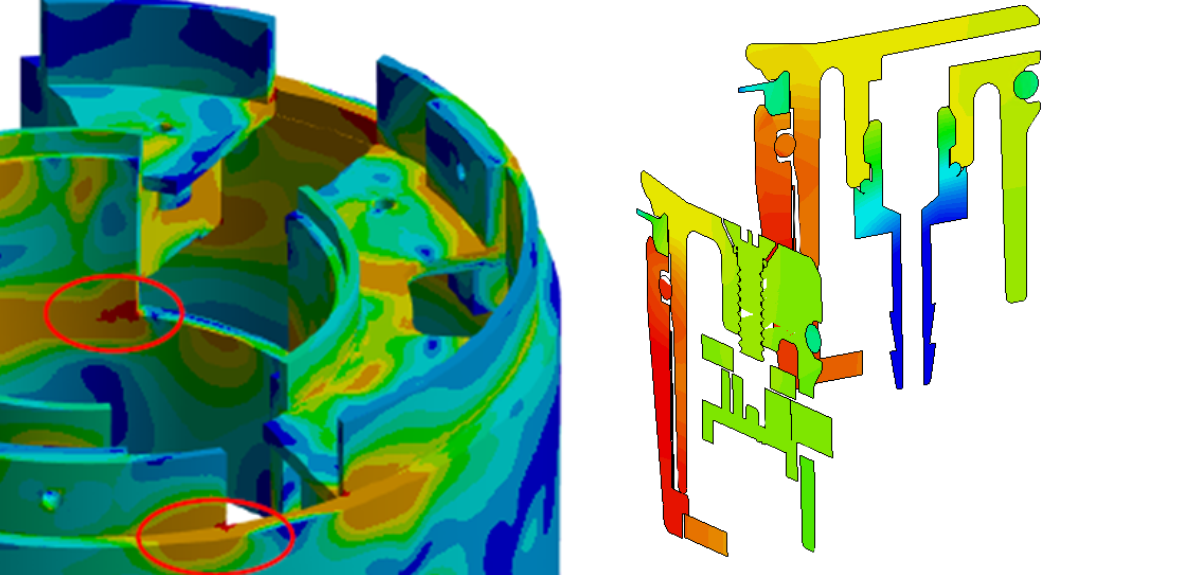

The flat-and-flush EV charging system developed in collaboration with Trojan Energy introduced many diverse new challenges that demanded all of our simulation capabilities in parallel: a true exercise in multiphysics simulation.

The steady-state (implicit solver), linear mechanical analysis of vehicle loading through the metal and reinforced-polymer static structure is the most straightforward. Non-linear analysis was applied to test the ability of innovative seal forms to tolerate size variation and sliding yet still withstand pressure. Time-based (explicit solver) impact analysis assessed the ability of exposed structures to withstand vandalism, correlated with ruthless physical testing! On the thermal side, analysis helped address the design of 22kW sliding electrical contacts by modelling the heat dissipation through mixed material assemblies in a compact, sealed environment, and evaluating resistive elements to prevent mechanisms from freezing in sub-zero conditions.

Across similar projects, fluidics simulation helps us to resolve ‘water management’ in cases where limited ingress is unavoidable with certain seals during use. Simulation helps us to confirm the droplet path to predetermined and safe sites.

Simulation as a Design Partner

Simulation is a broader and more fitting term for this CAD-enabled suite of technologies than pure analysis. Its application is not only multiphysics, but also iterative and multi-purpose. Combined with CAD, it enhances every stage of the design process.

In early concept and feasibility, it makes it practical to explore more ambitious goals, and to compare competing concepts quickly, leading to better choices. In the design phase, it can help optimise designs and quantify results and risk before committing to more costly prototypes and testing, the results of which can be correlated for better prediction. In the design detailing phase, simulation allows for designs to be assessed at worst-case size or material limits and be operated in difficult-to-recreate conditions. This virtual verification can ensure there is sufficient safety factor and reliability for the anticipated duty.

At PDD, we have likened the ‘crystal-ball’ ability afforded by multiphysics simulation to ‘looking before you leap’. It has helped us deliver dramatic and effective innovations for our clients in a more expedient, manageable and quality-assured way.

The Future: AI and Beyond

The computing revolution has now almost turned full circle. Local machines that once served as simple terminals now primarily connect through high-speed networks to supercomputers, once again occupying entire floors of chilled data centres. Today, graphics-accelerated and massively parallel processing allows AI to process vast datasets, combining material science, knowledge of prior structures and models for rapid trial, error and optimisation. This adds agility, experience and fresh insight to simulations, revealing possibilities, issues and solutions that might otherwise be disregarded.

Looking ahead, design challenges that emerge from today’s drive towards net zero, new forms of mobility, neural-computer integration and the sustainable use of resources beyond Earth will demand unprecedented creativity and collaboration. As these ambitions evolve into practical realities, multiphysics simulation, enhanced by AI and quantum computing and entanglement communication will play a vital role in helping us anticipate and address them what we cannot yet fully articulate or envision.

At PDD, we continue to explore how simulation and emerging technologies can advance innovation and shape solutions that are visionary, human-centred and sustainable. If you would like to learn more, please get in touch.